When it comes to precision drilling, not all drill bits are created equal. One special design that has become increasingly popular in industrial applications is the parabolic flute drill. But what exactly is it, and why is it widely used in manufacturing and metalworking today?

What Is a Parabolic Flute Drill?

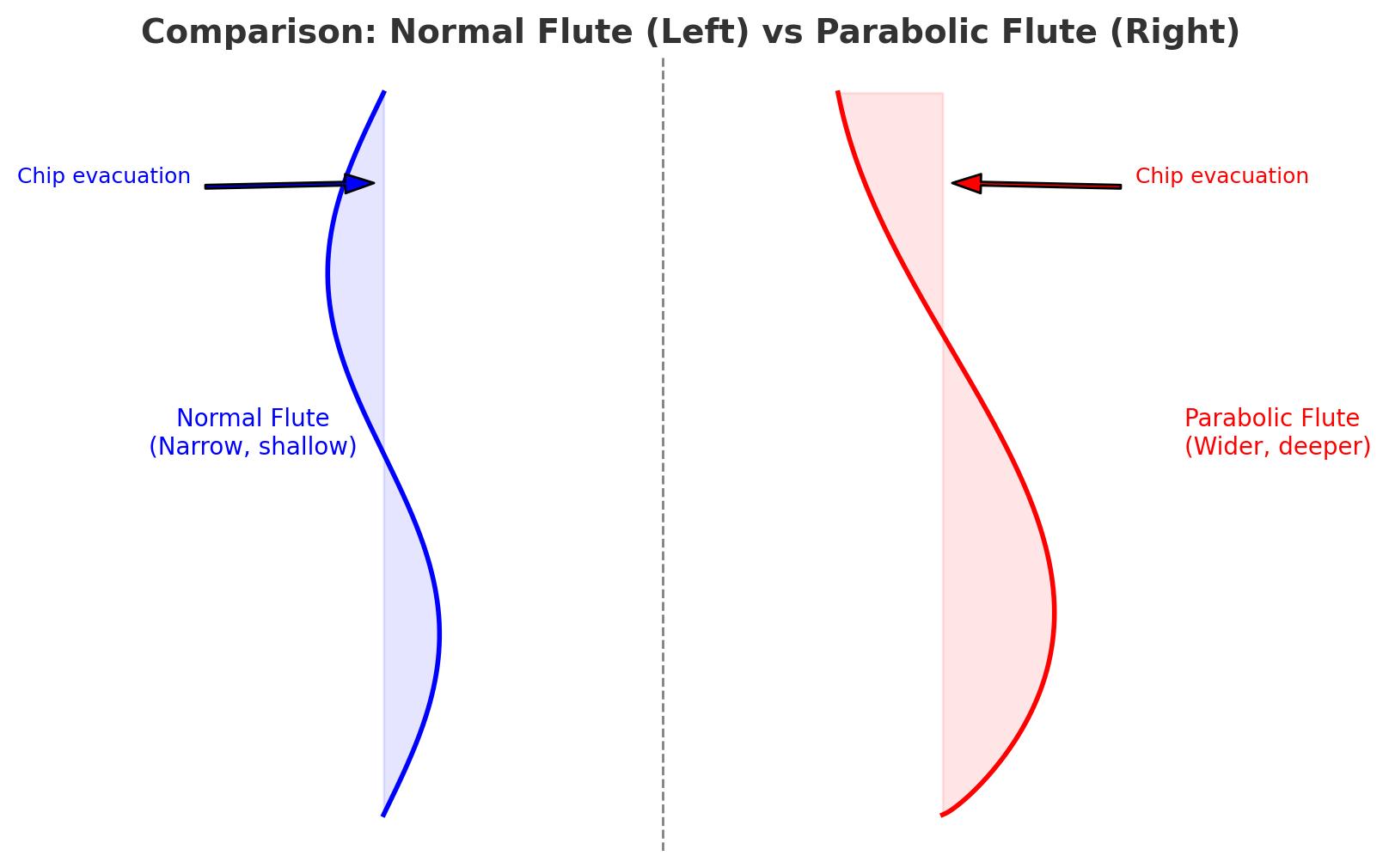

A parabolic flute drill is a type of twist drill bit with a uniquely shaped flute. Unlike standard drill bits that have relatively narrow and straight flutes, the parabolic flute is wider and deeper. This geometry creates extra space for chips to move out of the hole, which is especially important when drilling deep holes.

Think of it like a highway: a wider road allows more cars to pass smoothly. In the same way, the parabolic flute provides a “wide road” for chips, keeping the drilling process clean and efficient.

Key Advantages of Parabolic Flute Drills

1.Superior Chip Evacuation

- The deeper flute allows chips to exit quickly.

- Prevents clogging inside the hole, which can damage both the drill and the workpiece.

2.Lower Heat and Friction

- Faster chip removal reduces friction.

- Less heat means longer tool life and more stable cutting performance.

3.Ideal for Deep-Hole Drilling

- Standard drills usually work best for shallow holes.

- Parabolic flute drills are designed to handle holes 3–7 times the drill diameter or more.

4.Better Surface Finish

- Smooth chip evacuation results in cleaner, more precise holes.

Where Are Parabolic Flute Drills Used?

Parabolic flute drills are widely applied in industries that demand accuracy and efficiency:

- Aluminum and Non-Ferrous Metals: Prevents chip sticking and clogging.

- Steel and Stainless Steel: Handles tougher materials while reducing heat.

- Aerospace, Automotive, and Manufacturing: Commonly used where deep, accurate holes are required.

Post time: Sep-09-2025