When it comes to drilling performance, geometry matters just as much as material. Choosing the right drill bit shape can make your work faster, cleaner, and more precise.

At Jiacheng Tools, we pay close attention to geometry details that directly affect cutting performance and tool life. Here are 4 key features to understand when selecting the right drill bit:

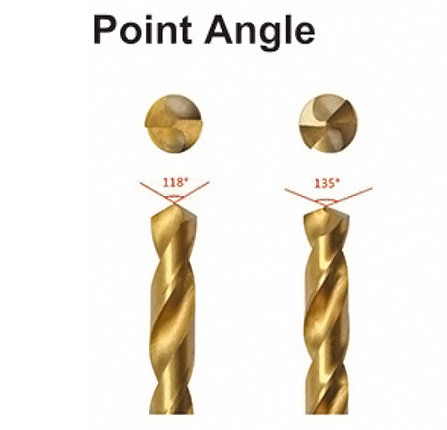

1. Point Angle

This is the angle at the tip of the drill.

• A sharper angle like 118° is perfect for soft materials such as wood or plastic.

• A flatter angle like 135° works better for hard metals — it improves accuracy and helps prevent the bit from wandering.

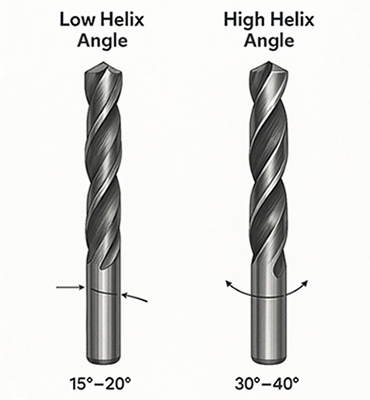

2. Helix Angle

The helix angle controls how steep the flutes spiral around the bit.

• Lower angles (like 15°–20°) offer more strength for drilling hard materials.

• Higher angles (like 30° or more) remove chips faster and are great for softer materials.

3. Flute Design

Flutes are the grooves that carry chips away from the cutting edge.

• Wider and deeper flutes help remove chips efficiently and reduce heat.

• Good flute design improves both drilling speed and hole quality.

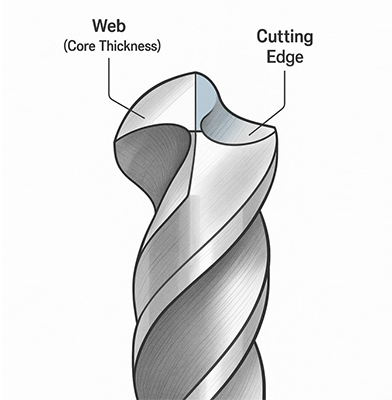

4. Web Thickness

This refers to the thickness of the drill bit's core.

• A thicker web gives the bit more strength and stability.

• A thinner web improves chip flow but may reduce strength.

Some bits are specially thinned at the center to balance both strength and cutting ease.

At Jiacheng Tools, we put geometry at the heart of our drill bit design. Each bit is carefully tested and refined to ensure it delivers the best performance for real-world applications. We work closely with our customers to recommend the most suitable geometry for their needs — because the right design truly makes a difference.

Whether it’s for general use or a highly specific task, we offer a wide range of options and custom solutions to match different materials, industries, and drilling requirements.

Post time: Jun-05-2025